I decided on cleaning my laptop fans today, which I’ve been procrastinating for about a year now because of this one screw. But I just can’t seem to open this with my screwdriver, since whatever I did back when I last opened it it’s nearly circular now. Is there a way to unscrew this?

Carefully dremel a slot in the screw head and use a flat head screwdriver.

Make sure you don’t get any dust into the electronics.

So if you have a dremel and steady hands, a cut off wheel can make your own slot for a straight Phillips.

Just be careful to not knick anything else. This is more of a last resort thing, but I’ve never had it not work.

Learn from my mistakes, mask off your laptop’s ports and vents before you do this

Ooof. Not something I’d have thought of myself…

Benefit of your hindsight it’s obvious… lol. How bad were the sparks?

Surprisingly quiet, one little ‘pop’ was the last I heard from that motherboard. On-board power supplies were a reasonable step forward but man are they not fault tolerant

Keyboard too?

Yes

Flathead/standard not a straight Philips.

Flathead is a description of the head profile, like panhead. Slotted is the screwdriver type that is just a single slot.

It could be a regional thing. Where I’m from a screw with a single straight slot can be called a flathead whether the actual head of the screw is flat or domed.

It gets called that everywhere. Most people never need to know the actual specs for a screw, so language diverges from the classification system.

I usually keep the corrections to myself, but when somebody else is already correcting someone and they say the wrong thing too it becomes hard.

I came here to say that

They make screw extractor bits with thread that winds the opposite way from the screw itself so that the bit drills into the screw while turning counterclockwise, but I don’t think that’s worth bothering with here (and I’ve never seen an extractor small enough). Just drill the head off with a normal drill bit. The body will stay stuck in the hole, but you’ll be able to take the cover off and laptops are usually held together by so many screws that a missing one won’t cause problems.

Try addinv a rubber band between the screw and the screwdriver, it adds friction which sometimes (usually not) helps

Old life hack that occasionally works for this is to use a rubber band. Grab a rubber band wide enough to cover the screw head, push the screwdriver into the screw through the rubber band, and pray it has enough grip to twist the screw loose. Good luck with whatever method you use.

Never in the history has that worked for me of doing laptop repair professionally.

Thank you. This is always in the list of handyman hacks, and using a rubberband has never worked for me either. I’m convinced 90% of the people recommending it are just repeating what they’ve heard and haven’t actually tried it.

I’ve tried it a dozen or so times, maybe worked 2-3 of them. I keep it in my arsenal of tricks because it’s quick and easy to try with no negative repercussions if it doesn’t work.

It’s worked for me but with a couple layers of insulation tape rather than a rubber band.

Old Nintendo security screws were easily overcome by melting the end of a pen tube (the clear plastic Bic’s were always my preference), and jamming it in there holding it still while it cooled. Could work in this case.

I have successfully done this with a fuse box.

Put a rubber band between screwdriver and screw, otherwise the other things already stated like CA glue, filing a flathead groove, or drilling the cap off

in the future use the appropriate sized driver and retire drivers when they become stripped

This. The rubber band trick works well for the first step. I came to say this.

The rubber band trick is great, and very low effort/cost. I want to say, though, that it can take substantially more force than it looks like it should on small screws like this. You also don’t have to use something shaped for the original driver of the screw. With the rubber to help it, a round cylinder a little smaller than the head of the screw can work very well.

Just so you know, OP, CA glue is a generic term for CyanoAcrylate glue, like Super Glue or Krazy Glue.

Bring out the KraGle!

If you have a Dremel, grind a slot into it and unscrew it.

If it has a hard backing, you can place a flat head screwdriver on it, give it a few taps, apply loads of pressure and turn it out.

If none of these are possible, a drop of CA adhesive on the screwdriver head, push it against the screw, make sure there is no excess leakage, then use a quick set spray. Once the screw has been turned out, use acetone to remove the glue.

If all of this fails, you gotta drill it. A hand crank drill, and a left handed bit. People seldom have these, so I assume this is your last resort.

Final bit of advice, hit the screw head a couple of times before you try any of these as it loosens the screw a tad. Also, sharpen an old screwdriver tip to just the width and thickness of what is left of the screw head slots. You should be able to find one that is already this size in those screwdriver tip sets

Good luck.

If you have a Dremel, grind a slot into it and unscrew it.

This has saved my ass many times. I keep one of those diamond coated wheels on a spare cutoff mandrel already mounted up pretty much specifically for this purpose.

Harbor Freight has a pretty cheap left handed drill bit set that is sometimes a lifesaver in these situations. Many times I just start drilling it with the left hand bit and often the bit grabs and unscrews the screw before even getting to the phase of trying the screw extractor on it. Sometimes not.

I was gonna say, my Harbor Freight Dremel has been a fantastic use of a couple bucks. I get tons of use from it.

Sadly no Dremel. I will try out a screw extractor and buy a few other screws before drilling or getting adhesive, thank you for your response!

Do you have a large Philips bit (like #3 or #4, the largest one that will fit in whats left of the screw)? You could try using that and tapping the end with a hammer (not too hard since its plastic) while gently twisting it. This usually shocks the screw and breaks it loose.

Take the drill bit out of your drill. Open the chuck up all the way and place it over the screw. If there is enough screw head there you might be able to grab it with the drill and just unscrew.

Edit: looking at the other picture makes me think it is recessed and that wouldn’t work then.

Cripes, it never even occurred to me that you could do this with a chuck. Thanks for expanding my mind.

Vampliers!

I work(ed) with old machines, and it was an absolute godsend. Prefer it after using penetrating spray on stuck screws.

Those look very interesting. Thank you!

I once had a screw on a laptop that wouldn’t unscrew and eventually somewhat lost its shape. I had asked my uncle for help, who gave me the solution. I think it was slightly less bad than this, but it might help:

- Apply WD40 around the edges of the screw, such that it could enter the hole

- Apply it to the screw head

- Hold your screwdriver in the hole and gently tap it with a hammer a couple of times

- Slowly attempt to screw it out, whilst applying firm downward pressure on the screw

Note that the amounts of WD40 you have to apply are tiny. We’re talking drops of the stuff. It might be best to attempt to spray something else, and use the residue on the nozzle to apply it

Jb weld a nut to it.

Also, G Flex is an epoxy formulated for plastics and West Systems has tutorials on their site.

In this case, I’d drill a small hole in the center, put CA or epoxy in it, then screw another screw into the epoxied hole and let it set up.

There’s no need for all that work. Just a dab of epoxy or glue right on top, the any appropriate sized nut on top of that.

Any drilling/dremel work just creates dust and metal shavings.

Drill in it, put fitting torx in hole, unscrew.

That usually works, however you need too much force to press the torx bit into the hole to do that on sensitive electronics. That screw is probably only threaded into plastic.

Looks like it sticks out a bit. Cut a slot in it and use a flathead.

Looks like sheet metal to me.

edit: right, laptop.

Depending how tight it is you could superglue something to it to turn it ?

I don’t really have superglue right now, and the screw looks like this far up, not sure it can be called tight or not.

(Screwdriver for comparison, couldn’t really find something better.)

You could also padding out the screwdriver tip or the screw hole. I’ve used sticky tape before, but again if its tight your pretty much out of luck…

That would have to be a pretty loose screw

Pretty much this - depending how much surface area and how good the glue is you might get it or you might snap that right off too. If it fails the next step is to carefully drill the screw out. A somewhat riskier operation but itll get it open

Maybe try a flat head screwdriver that’ll fit diagonally across where there’s some grip left?

Seconded. I’ve loosened many shredded screws this way.

Also, one can use a hack saw or similar to cut a slit into the screw head, that way you’re more or less guaranteed to fit a flathead driver properly.I do have a gigantic flathead but it doesn’t exactly fit, though I will get one in the morning and try out your advice if I can’t get it out by then. Thank you!

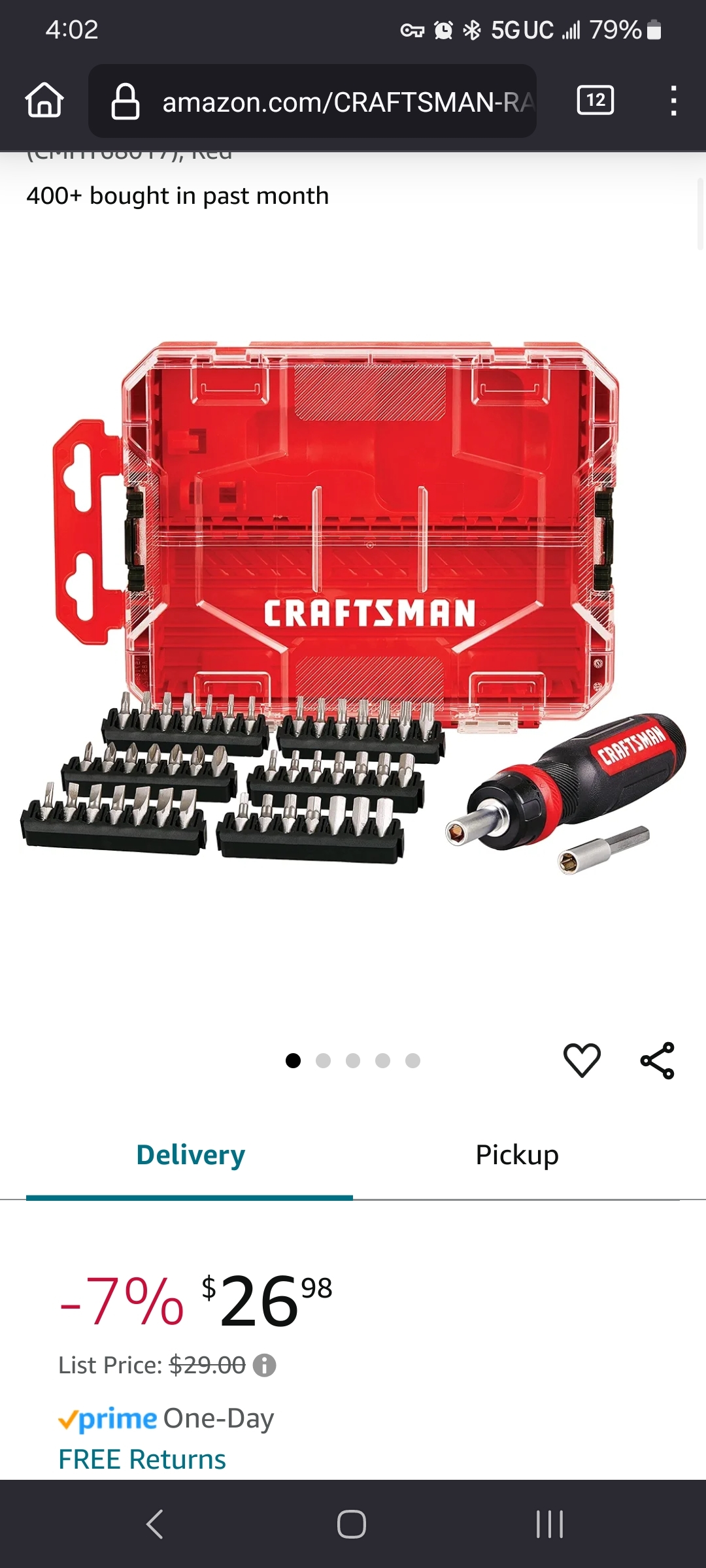

Get something like this, but look for something that uses a 1/4” hex end for using it with a regular bit driver screwdriver if you don’t have a drill that can go slowly in reverse.

Get one of these cheap kits with multiple bits and try the largest Philips bit. Not necessarily the one pictured as this is more expensive than most:

I prefer the rubber band trick first but usually when I get them down to this point I’ll use a smaller flathead from a jeweler set, see if you can find something that fits in between the two opposing tines of the Philips